*JPX Separators now standard with flanged connections

**For finer filtration: eJPX Premium Efficiency Separator

LAKOS Separators are designed to operate continuously with no routine shutdowns for cleaning or maintenance.

Reduces defects, replacement parts, and maintenance cycles, while increasing efficiency and product consistency.

No screens or filter elements to clean or replace. Centrifugal action removes debris without restricting flow or the mess of a filter.

| Models* |

Downloads |

Flow Range |

Inlet/ Outlet Size** |

Connections | Purge Size Male NPT |

Solids Collection Capacity |

Dry Weight |

||||

| US GPM | m3/hr | Inlet/ Outlet |

Top Access |

gal. | liters | lbs. | kg | ||||

| JPX-0004 | DWG PDF | 4-10 | 1-2.5 | 1/2″ | F | G | 1″ | 0.09 | 0.3 | 33 | 15 |

| JPX-0010 | DWG PDF | 10-20 | 2.5-4.5 | 3/4″ | F | G | 1″ | 0.11 | 0.4 |

54 | 25 |

| JPX-0016 | DWG PDF | 16-30 | 4-7 | 1″ | F | G | 1″ | 0.15 | 0.6 |

60 | 27 |

| JPX-0028 | DWG PDF | 28-45 | 7-10 | 1-1/4″ | F | G | 1-1/2″ | 0.15 | 0.6 |

88 | 40 |

| JPX-0038 | DWG PDF | 38-65 | 9-15 | 1-1/2″ | F | G | 1-1/2″ | 0.4 | 1.5 |

116 |

53 |

| JPX-0060 | DWG PDF | 60-100 | 14-23 | 2″ | F | G | 1-1/2″ | 0.8 | 3.0 | 164 | 74 |

| JPX-0085 | DWG PDF | 85-145 | 19-33 | 2-1/2″ | F | G | 1-1/2″ | 0.8 |

3.0 | 244 |

111 |

| JPX-0130 | DWG PDF | 130-225 | 30-51 | 3″ | F | G | 1-1/2″ | 0.8 | 3.0 | 258 |

117 |

| JPX-0200-L | DWG PDF | 200-325 | 45-74 | 4″ | F | G | 1-1/2″ | 1.6 |

6.1 |

469 |

213 |

| JPX-0200-V | DWG PDF | 200-325 | 45-74 | 4″ | F | G | 1-1/2″ | 4.4 | 16.7 | 408 |

185 |

| JPX-0285-L | DWG PDF | 285-525 | 65-120 | 4″ | F | G | 1-1/2″ | 2.1 | 7.9 | 603 | 274 |

| JPX-0285-V | DWG PDF |

285-525 | 65-120 | 4″ | F | G | 1-1/2″ | 5.4 |

20.5 | 512 | 232 |

| JPX-0450-L | DWG PDF | 450-825 | 102-187 | 6″ | F | G | 1-1/2″ | 2.8 |

10.6 | 770 | 350 |

| JPX-0450-V | DWG PDF |

450-825 | 102-187 | 6″ | F | G | 1-1/2″ | 6.7 |

25.4 | 728 | 330 |

| JPX-0650-L | DWG PDF | 650-1,200 | 150-275 | 6″ | F | G | 1-1/2″ | 4.3 | 16.3 | 1000 | 454 |

| JPX-0650-V | DWG PDF | 650-1,200 | 150-275 | 6″ | F | G | 1-1/2″ | 10.4 | 39.4 | 959 | 436 |

| JPX-1160-L | DWG PDF | 1,160-2,150 | 265-490 | 8″ | F | G | 1-1/2″ | 8.6 | 32.6 | 1,449 | 657 |

| JPX-1160-V | DWG PDF | 1,160-2,150 | 265-490 | 8″ | F | G | 1-1/2″ | 20.5 | 77.6 | 1,433 | 650 |

| JPX-1850-L | DWG PDF | 1,850-3,400 | 420-775 | 10″ | F | F | 2″ | 15.0 | 56.8 | 2,233 | 1,004 |

| JPX-1850-V | DWG PDF | 1,850-3,400 | 420-775 | 10″ | F | F | 2″ | 31.5 | 119.2 | 2,327 | 1,055 |

| JPX-2650-L | DWG PDF | 2,650-4,900 | 600-1,115 | 12″ | F | F | 2″ | 23.5 | 89.0 | 3,810 | 1,720 |

| JPX-2650-V | DWG PDF | 2,650-4,900 | 600-1,115 | 12″ | F | F | 2″ | 51.1 | 193.4 | 3,315 | 1,504 |

| JPX-4200-L | DWG PDF | 4,200-7,800 | 950-1,775 | 16″ | F | F | 3″ | 52.2 | 197.6 | 6,422 | 2,913 |

| JPX-4200-V | DWG PDF | 4,200-7,800 | 950-1,775 | 16″ | F | F | 3″ | 99.3 | 375.9 | 6,368 | 2,888 |

| JPX-6700-L | DWG PDF | 6,700-12,750 | 1,520-2,895 | 20″ | F | F | 3″ | 81.0 | 306.6 | 9,282 | 4,210 |

| JPX-6700-V | DWG PDF | 6,700-12,750 | 1,520-2,895 | 20″ | F | F | 3″ | 162.3 | 614.4 | 8,929 | 4,050 |

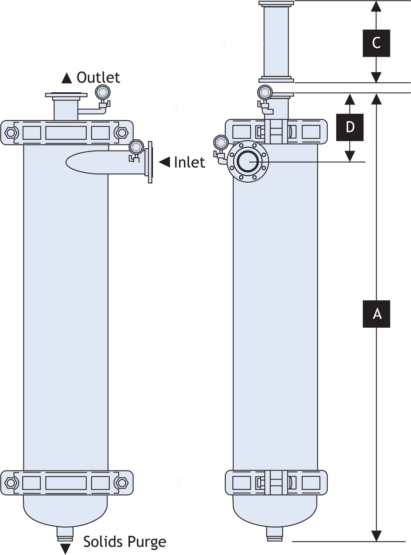

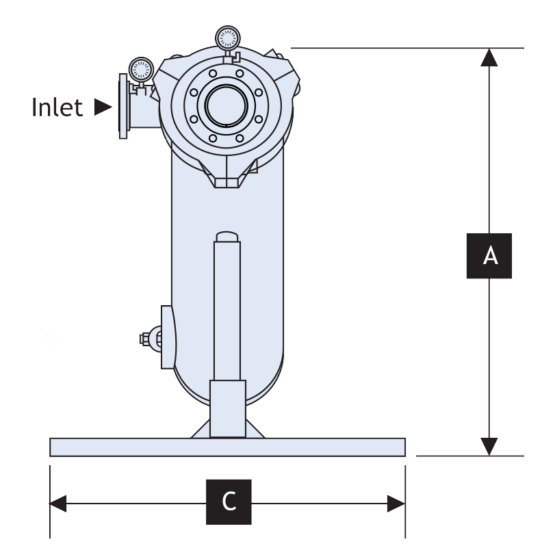

* Models ending with “L” are low profile; “V” for vertical profile

** Inlet/Outlet come standard with ANSI flanges (DIN or JIS flanges available upon request)

Note:

1. F = flanged connection

2. G = grooved connection

3. Maximum pressure rating: 150 psi(10.3 bar). Consult factory for higher pressure requirements

4. Pressure loss range: 3-12 psi (.2-.8 bar).

5. Maximum temperature rating: 180°F (82.2°C). Consult factory for higher temperatures

6. Maximum particle size: JPX-0016 and smaller – 0.25 inch (6 mm); all other models – 0.375 inch (9 mm)

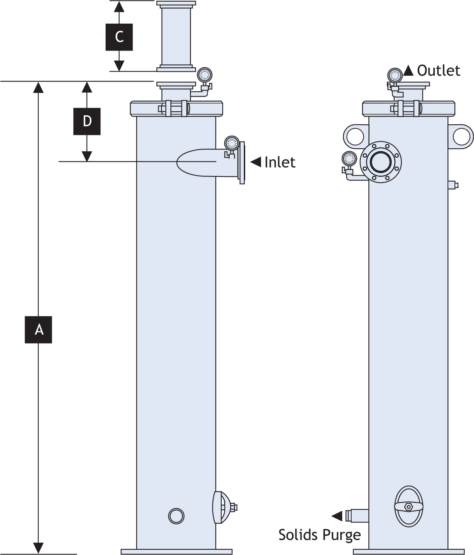

| Models | Dim A | Dim B | Dim C | Dim D | ||||

| inches | mm | inches | mm | inches | mm | inches | mm | |

| JPX-0004 | 27-13/16″ | 706 | 7-1/2″ | 191 | 6″ | 152 | 7-7/8″ | 200 |

| JPX-0010 | 32-1/16″ | 815 | 8-15/16″ | 227 | 7″ | 178 | 7-7/8″ | 200 |

| JPX-0016 | 33-3/8″ | 882 | 9-3/16″ | 233 | 7″ | 178 | 8-3/16″ | 208 |

| JPX-0028 | 37-5/16″ | 948 | 11-1/4″ | 286 | 7″ | 178 | 8-7/16″ | 214 |

| JPX-0038 | 39-7/8″ | 1,013 | 11-3/8″ | 289 | 14″ | 356 | 8-1/2″ | 216 |

| JPX-0060 | 49-5/16″ | 1,252 | 14-11/16″ | 373 | 18″ | 457 | 9-3/8″ | 238 |

| JPX-0085 | 57-1/8″ | 1,451 | 14-11/16″ | 373 | 18″ | 457 | 9-1/2″ | 241 |

| JPX-0130 | 60-1/4″ | 1,530 | 14-11/16″ | 373 | 21″ | 533 | 11″ | 279 |

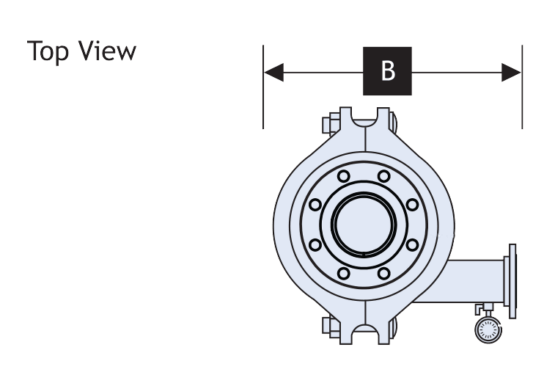

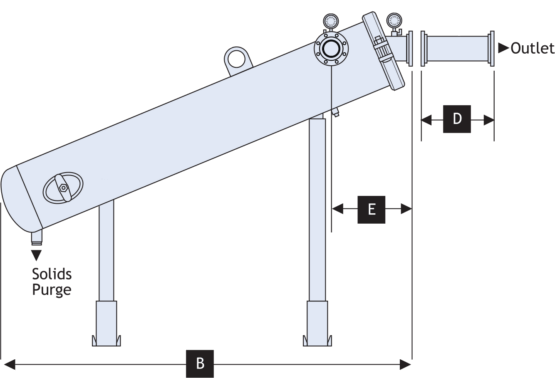

| Models | Dim A | Dim B | Dim C | Dim D | Dim E | |||||

| inches | mm | inches | mm | inches | mm | inches | mm | inches | mm | |

| JPX-0200-L | 70-15/16″ | 1,802 | 65-11/16″ | 1,668 | 40″ | 1,016 | 26″ | 660 | 13-3/4″ | 350 |

| JPX-0285-L | 78-9/16″ | 1,995 | 79-15/16″ | 2,030 | 40″ | 1,016 | 26″ | 660 | 16-3/8″ | 417 |

| JPX-0450-L | 85-5/8″ | 2,175 | 94-1/2″ | 2,400 | 40″ | 1,016 | 28″ | 711 | 15-3/4″ | 400 |

| JPX-0650-L | 90-5/8″ | 2,302 | 106-5/8″ | 2,708 | 40″ | 1,016 | 28″ | 711 | 18-3/8″ | 466 |

| JPX-1160-L | 104-3/4″ | 2,661 | 127-11/16″ | 3,243 | 40″ | 1,016 | 36″ | 914 | 22-5/16″ | 566 |

| JPX-1850-L | 113-9/16″ | 2,884 | 150-7/8″ | 3,832 | 40″ | 1,016 | 38″ | 965 | 34-5/8″ | 879 |

| JPX-2650-L | 126-5/8″ | 3,216 | 166-5/8″ | 4,232 | 60″ | 1,524 | 42″ | 1,067 | 37-1/2″ | 952 |

| JPX-4200-L | 145-1/4″ | 3,689 | 211-3/16″ | 5,364 | 60″ | 1,524 | 46″ | 1,168 | 48-1/8″ | 1,223 |

| JPX-6700-L | 170-1/4″ | 4,324 | 248-7/16″ | 6,310 | 60″ | 1,524 | 52″ | 1,321 | 57-1/2″ | 1,460 |

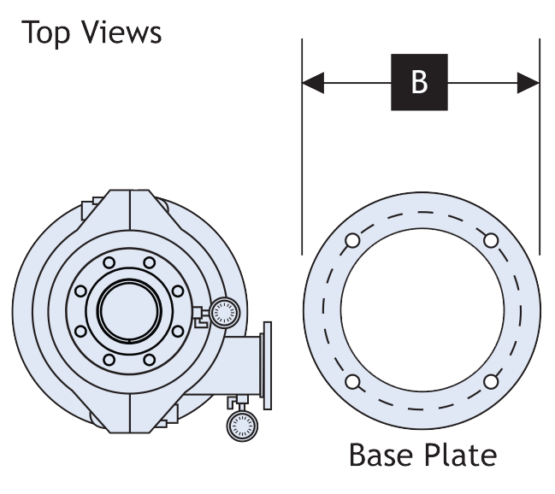

| Models | Dim A | Dim B | Dim C | Dim D | ||||

| inches | mm | inches | mm | inches | mm | inches | mm | |

| JPX-0200-V | 74-3/16″ | 1,884 | 16″ | 406 | 26″ | 660 | 12-1/8″ | 302 |

| JPX-0285-V | 80-1/16″ | 2,034 | 18″ | 457 | 26″ | 660 | 15-1/2″ | 368 |

| JPX-0450-V | 95-1/8″ | 2,416 | 20″ | 508 | 28″ | 711 | 13-7/8″ | 352 |

| JPX-0650-V | 107-7/8″ | 2,740 | 22″ | 559 | 28″ | 711 | 16-1/4″ | 413 |

| JPX-1160-V | 128-5/8″ | 3,267 | 26″ | 660 | 36″ | 914 | 19-3/8″ | 492 |

| JPX-1850-V | 148-13/16″ | 3,780 | 32″ | 813 | 38″ | 965 | 28-7/16″ | 723 |

| JPX-2650-V | 169-1/4″ | 4,299 | 36″ | 914 | 42″ | 1,067 | 31-1/2″ | 800 |

| JPX-4200-V | 209-3/16″ | 5,314 | 44″ | 1,118 | 46″ | 1,168 | 43-1/8″ | 1,095 |

| JPX-6700-V | 251-1/4″ | 6,382 | 52″ | 1,321 | 52″ | 1,321 | 49-7/8″ | 1,268 |

Automatic Purging Adders:

APP Pneumatic Pinch Valve, ABV Electric Ball Valve, AFS Pneumatic Ball Valve Fail-Safe

Accessories:

Grooved Coupling Spools, Grooved Couplings, Flanged Spools

ASME

Internal 3M Scotchkote Coating

Stainless Steel Material

Answer: Flow rate is the most important factor in determining separator size because all LAKOS Separators operate within a prescribed flow range. Pipe size is not a factor in model selection so do not use your existing pipe size to determine the separator size. Required separator size is often, but not always, smaller than the existing piping, and appropriate hardware is used to match the inlet/outlet size with existing piping.

Answer: While there are many LAKOS Separators still in service after 15-25 years, there are many variables to the longevity of a LAKOS Separator. It can generally be expected to last as long as any other materials of similar construction in that system. Environment, fluid chemical make-up, flow, the material of construction, type of solids, and maintenance purging are all important factors to the life of a separator. It is important to consider all these factors when purchasing a separator. Providing LAKOS with details about your application will ensure your separator meets or exceeds the life expected through your purchase. Consult your LAKOS factory representative to obtain the life expectancy in your specific application.

Answer: The LAKOS Separator is capable of working with any liquid that has a viscosity less than 100 SSU. The solids to be separated must also have a specific gravity at least 1.5 greater than the fluid. The greater the specific gravity of the separable solids and the lower the viscosity of the liquid, the better the LAKOS Separator will work. A good rule of thumb: if the solids settle within 3-4 minutes in your liquid, they will likely be separable with a LAKOS Separator.

Answer: Solids-removal efficiency is affected by several factors, including the difference in specific gravity between the solids and the carrying liquid, the viscosity of the liquid, the particle shape, and any purging enhancement techniques. In general, with a specific gravity ratio of 2.6 (e.g. quartz sand in freshwater), liquids of 31 SSU viscosity, and generally round particles, a single pass through a separator predictably removes 98% of particles 74 microns (0.0029 inches) and larger. Appreciable quantities of particles finer than 74 microns are also removed, as well as particles of lighter specific gravity. Higher specific gravities (like mill scale in water, where SG=5.7) result in much finer levels of filtration.

Recirculating systems (running the fluid through one or more separators continuously) can also result in appreciable removal of particles down as fine as 5 microns.

Contact LAKOS for assistance determining performance expectations on your specific application.

Answer: As a standard, most separators are available in mild carbon steel and 304L/316L-series stainless steels. Specially designed separators can also be constructed in most weldable metals, including, but not limited to: super duplex stainless steels, chrome-moly, titanium, Hastelloy, nickel alloys, and cupronickel. In special cases, separators can also be fabricated in plastic or fiberglass. For materials other than carbon and stainless steel, consult with LAKOS on the availability of your specific material requirements.

Answer: The maximum solids loading on LAKOS Separators is recommended to be less than 1% by volume. While 1% may seem low, keep in mind that 1% in a small 100 GPM system is 1 gallon of solids every minute, or 1,440 gallons (twenty-six 55-gallon drums) of solids per day. SMP Separators for residential use are not recommended to exceed 0.25% by volume. ILB Series Separators are not recommended to exceed 0.50% by volume. If your application exceeds these limitations, please consult your factory representative for proven alternatives.

Answer: LAKOS factory-built purge controllers (ABV, ABV2, AKE, APP, AFS, EFS) do not have factory-set timings. The required purge frequency and durations vary depending on flow rates, solids concentrations, type of solids, etc. The controller time settings must be set at installation and LAKOS literature LS-608 can be used to help establish purge duration and frequency based on the application.

Answer: To determine the necessary purge frequency, purge often at first and calculate the proper rate based on the expected volume of separated solids. Purge duration should be long enough to evacuate the purge chamber AND clear the entire length of the purge piping of all solids. This is usually indicated by a change in the color of the purged liquid from dark to light. The time between purges should never exceed the time it takes to fill 1/3 of the collection chamber volume, based on the expected solids load and the separator’s purge collection volume, as indicated in the separator’s literature. Refer to LS-608 for additional information on calculating purge frequency and duration.

Answer: LAKOS separators and sand filters are both designed to remove solids from liquids, but have advantages over each other depending on the application.

A separator is designed to remove solids with a specific gravity at least 1.5 times that of the carrying liquid. Separators require very little, if any, maintenance because they have no moving parts. The pressure loss across a separator is predictable and steady and only varies with flow rate. Separators require minimum liquid loss for the purging of collected solids, and can also be equipped with an optional solids recovery vessel that can eliminate liquid loss. However, separators do not generally help with liquid clarity (turbidity) and are ineffective on organic material, such as algae.

A sand media filter is designed to remove finer solids (down to 5 microns in size) with low specific gravities. Sand filters are used when finer filtration and liquid clarity (turbidity reduction) are a requirement. Sand filters do require more operational maintenance (more moving parts) and use more liquid for backwashing of the sand bed to remove the collected solids. Pressure loss across a media filter varies, as solids are collected and enter a backwash cycle when they reach a predetermined pressure loss. However, sand media filters are very efficient at removing a wide variety of light, organic solids.

Answer: Standard maximum temperature rating for operating most LAKOS Separators is 180°F. The exceptions are SMP Separators, which have a maximum temperature of 120°F. LAKOS can easily accommodate higher temperatures with custom separators.

Answer: Standard maximum pressure rating for most LAKOS Separators is 150 psi. The exceptions are the SMP Separators, which have a maximum pressure rating of 100 psi. Contact the factory for higher pressures; LAKOS can accommodate pressures up to 3000 psi through custom separators.

Answer: Yes, we can manufacture a separator with a Canadian Registration Number (CRN). We must know the Province or Territory the vessel is to be located so we can contact the registration controlling agency within that Province or Territory to determine the cost and lead time.