*Product color may vary depending on size

*Product color may vary depending on size

| CTS Filter Models |

Pump HP |

Pump Inlet |

Surface Area (sq. ft.) |

Flow Rate @ 20 GPM/ sq. ft. |

Media Loading (cu. ft.) |

Weight (lbs.) | ||||

| MediaGem 475 | MediaGem 55 | Filter | Media | Shipping | Operating | |||||

| CTS-54-318 | 7.5 | 4 FLG | 15.9 | 318 | 18.00 | 34.00 | 2,339 | 5,434 | 7,773 | 12,215 |

| CTS-60-392 | 7.5 | 5 FLG | 19.6 | 392 | 23.00 | 42.00 | 2,716 | 6,758 | 9,474 | 14,993 |

| CTS-66-474 | 10 | 5 FLG | 23.8 | 474 | 29.00 | 51.00 | 2,962 | 8,397 | 11,359 | 18,209 |

| CTS-72-566 | 10 | 5 FLG | 28.3 | 566 | 37.00 | 64.00 | 3,362 | 10,374 | 13,736 | 22,444 |

| CTS-78-664 | 15 | 5 FLG | 33.2 | 664 | 47.00 | 75.00 | 3,752 | 12,261 | 16,013 | 26,855 |

| CTS-84-770 | 15 | 6 FLG | 38.5 | 770 | 56.00 | 87.00 | 4,216 | 14,783 | 18,999 | 31,296 |

| CTS-90-884 | 15 | 6 FLG | 44.2 | 884 | 68.00 | 100.00 | 4,345 | 17,346 | 21,691 | 36,088 |

| CTS-96-1006 | 20 | 6 FLG | 50.2 | 1006 | 81.00 | 136.00 | 6,034 | 22,430 | 28,464 | 42,654 |

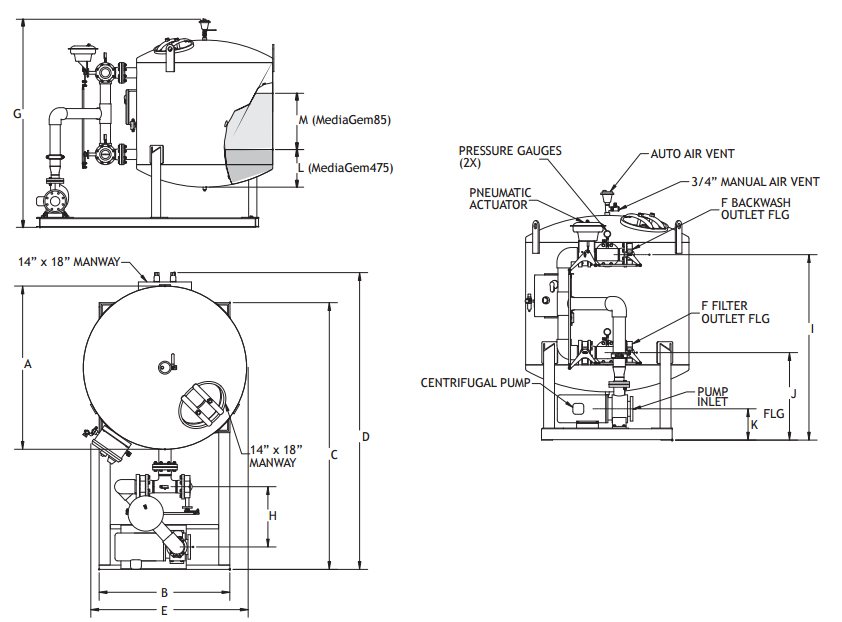

| CTS Filter Model |

Dim A |

Dim B | Dim C | Dim D | Dim E | Dim F | Dim G | Dim H |

Dim I | Dim J | Dim K | Dim L |

Dim M |

| inches | inches | inches | inches | inches | inches | inches | inches | inches | inches | inches | inches | inches | |

| CTS-54 | 54.0 | 43.50 | 93.0 | 102.69 | 61.19 | 4.0 | 91.0 | 19.69 | 68.19 | 32.19 | 11.50 | 17.06 | 25.66 |

| CTS-60 | 60.0 | 48.0 | 98.0 | 108.88 | 62.0 | 4.0 | 91.75> | 19.69 | 68.19 | 32.19 | 11.50 | >17.06 | 25.71 |

| CTS-66 | 66.0 | 52.0 | 103.0 | 114.88 | 66.19 | 4.0 | 93.50 | 19.81 | 68.19 | 32.19 | 11.50 | 17.06 | 25.71 |

| CTS-72 | 72.0 | 56.38 | 106.0 | 118.75 | 72.0 | 6.0 | 96.50 | 15.38 | 69.19 | 33.19 | 12.81 | 20.32 | 27.13 |

| CTS-78 | 78.0 | 60.50 | 113.0 | 126.63 | 78.0 | 6.0 | 97.25 | 17.25 | 69.19 | 33.19 | 12.81 | <20.32 | 27.10 |

| CTS-84 | 84.0 | 66.50 | 118.18 | 131.81 | 84.0 | 6.0 | 103.88 | 18.94 | 75.19 | 39.19 | 14.19 | 20.32 | 27.11 |

| CTS-90 | 90.0 | 71.0 | 126.18 | 140.69 | 90.0 | 6.0 | 105.69 | 20.69 | 76.19 | 40.19 | 14.19 | 20.32 | 27.14 |

| CTS-96 | 96.0 | 77.50 | 142.50 | 156.75 | 96.0 | 8.0 | 115.69 | 25.56 | 84.38 | 43.38 | 16.38 | 22.72 | 32.50 |

| CTS Filter Model |

Dim A |

Dim B | Dim C | Dim D | Dim E | Dim F | Dim G | Dim H |

Dim I | Dim J | Dim K | Dim L |

Dim M |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | |

| CTS-54 | 1372 | 1105 | 2362 | 2608 | 1554 | 102 | 2311 | 500 | 1732 | 818 | 292 | 433 | 652 |

| CTS-60 | 1524 | 1219 | 2489 | 2766 | 1575 | 102 | 2330 | 500 | 1732 | 818 | 292 | 433 | 653 |

| CTS-66 | 1676 | 1321 | 2616 | 2918 | 1681 | 102 | 2375 | 503 | 1732 | 818 | 292 | 433 | 653 |

| CTS-72 | 1829 | 1432 | 2692 | 3016 | 1829 | 152 | 2451 | 391 | 1757 | 843 | 325 | 516 | 689 |

| CTS-78 | 1981 | 1537 | 2870 | 3216 | 1981 | 152 | 2470 | 438 | 1757 | 843 | 325 | 516 | 688 |

| CTS-84 | 2134 | 1689 | 3002 | 3348 | 2134 | 152 | 2639 | 481 | 1910 | 995 | 360 | 516 | 688 |

| CTS-90 | 2286 | 1803 | 3205 | 3574 | 2286 | 152 | 2685 | 526 | 1935 | 1021 | 360 | 516 | 689 |

| CTS-96 | 2438 | 1969 | 3620 | 3981 | 2438 | 203 | 2939 | 649 | 2143 | 1102 | 416 | 577 | 826 |

ASME

Internal 3M Scotchkote Coating

Stainless Steel Material

Answer: Media filtration sand requirements are based on the filter’s downstream equipment needs. In the case of micro-irrigation system protection, the minimum orifice diameter of the devices (emitters, drip tape, etc.) will generally dictate the filtration level required. Once this orifice size has been determined, the following guidelines will be helpful:

Sand media used Filtration levels

#20 Filter Sand 200 – 250 mesh (74-63 microns)

#16 Filter Sand 150 – 200 mesh (105-74 microns)

#12 Filter Sand 120 – 150 mesh (125-105 microns)

Using media sand finer than required will cause slightly higher system pressure losses, and more frequent backwashing, so only use what is required to protect your downstream equipment.

Answer: As a rule of thumb, LAKOS uses a sizing factor of 1 GPM per square foot of basin area to determine the required size of a Tower Clean (TC) system. Using this factor, multiply the square footage of the cooling tower basin (L x W) by 1 GPM / sq. ft. This gives the basic flow rate for sizing the TC system. Tower Clean literature LS-710 can also be used as a reference for more information and equipment selections.

For industrial applications or very heavy solids loadings, consult LAKOS for recommended basin sweeping flow rates.

Answer: LAKOS separators and sand filters are both designed to remove solids from liquids, but have advantages over each other depending on the application.

A separator is designed to remove solids with a specific gravity at least 1.5 times that of the carrying liquid. Separators require very little, if any, maintenance because they have no moving parts. The pressure loss across a separator is predictable and steady and only varies with flow rate. Separators require minimum liquid loss for the purging of collected solids, and can also be equipped with an optional solids recovery vessel that can eliminate liquid loss. However, separators do not generally help with liquid clarity (turbidity) and are ineffective on organic material, such as algae.

A sand media filter is designed to remove finer solids (down to 5 microns in size) with lower specific gravities. Sand filters are used when finer filtration and liquid clarity (turbidity reduction) are a requirement. Sand filters do require more operational maintenance (more moving parts) and use more liquid for backwashing of the sand bed to remove the collected solids. Pressure loss across a media filter varies, as solids are collected and enter a backwash cycle when they reach a predetermined pressure loss. However, sand media filters are very efficient at removing a wide variety of light, organic solids.

Answer: It is recommended that backwashing should take place at an interval when it is anticipated the filter system will have a 7 psi pressure drop. This 7 psi differential is in addition to the normal operating pressure drop when the filter is clean. If the filter media does not achieve this differential over 24 hours, it is recommended that the filter be backwashed once a day as a minimum.