Wash Water Reclaimed for High Pressure Use

Wash Water Reclaimed for High Pressure Use

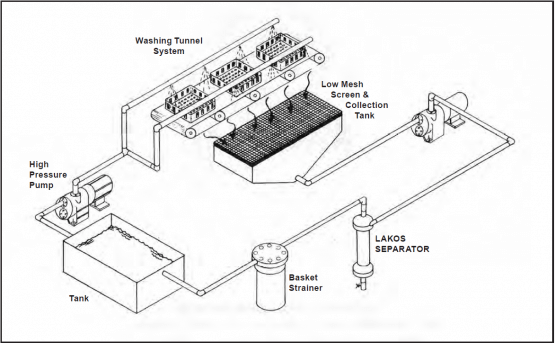

Minimizing abrasive wear to both a high pressure pump and a series of fine-orifice spray nozzles, H & R Industries, Inc. of Grand Rapids, Michigan attributes, in large part, the successful re-use of gritty wash water to a Lakos Separator. The system, a “washing tunnel” designed to clean plastic lugs which transport blueberries, utilizes a 900 psi (616 N/m2 x 104) high-pressure piston pump and 20 high-pressure nozzles. Says David A. Herr of H & R Industries, “This system simply wouldn’t have worked without effective filtration. Sand, grit and other particles would have worn out the pump and plugged the nozzles. We knew that, so we designed the Lakos Separator right into the original plans.”

The wash water, immediately after spraying, falls through a low-mesh screen to remove leaves, twigs and large material enroute to a collection tank. Pumped directly through the Lakos Separator from that tank, the water then passes through a final-stage basket filter before reaching another tank. The water is then sufficiently particle-free to pump at high pressure through the nozzles once again. A manual valve facilitates the purging of separated solids from the Lakos Separator.

Others who have used Lakos Separators for similar applications:

MITSUBISHI COAL MINING; Hokkaido Island, Japan

PIXLEY RICHARDS; Plymouth, Massachusetts

MONROE-WHYLIE; Clovelly Park, Australia

INDUSTRIAL WASHING MACHINE COMPANY; Matawan, New Jersey

FORD MOTOR COMPANY; Batavia, Ohio

SIDNEY COOKE FASTENERS PTY.; Ridleyton, Southern Australia

INDUSTRIAL METAL FABRICATIONS; Detroit, Michigan

FISHER/GUIDE; Anderson, Indiana

IMPACT INDUSTRIES; Sandwich, Illinois

SEPTA; Philadelphia, Pennsylvania

BRANDON CAR WASH; Brandon, Florida

RYKO MANUFACTURING; Rimes, Iowa

AQUA JET SYSTEMS, INC.; Arvada, Colorado

N/S CORPORATION; Inglewood, California

FLEETWASH, INC.; Brewster, New York

ISUZU MOTOR COMPANY; Fujisawa, Japan

MITSUBISHI MOTORS; Clovelly Park, Southern Australia