Background

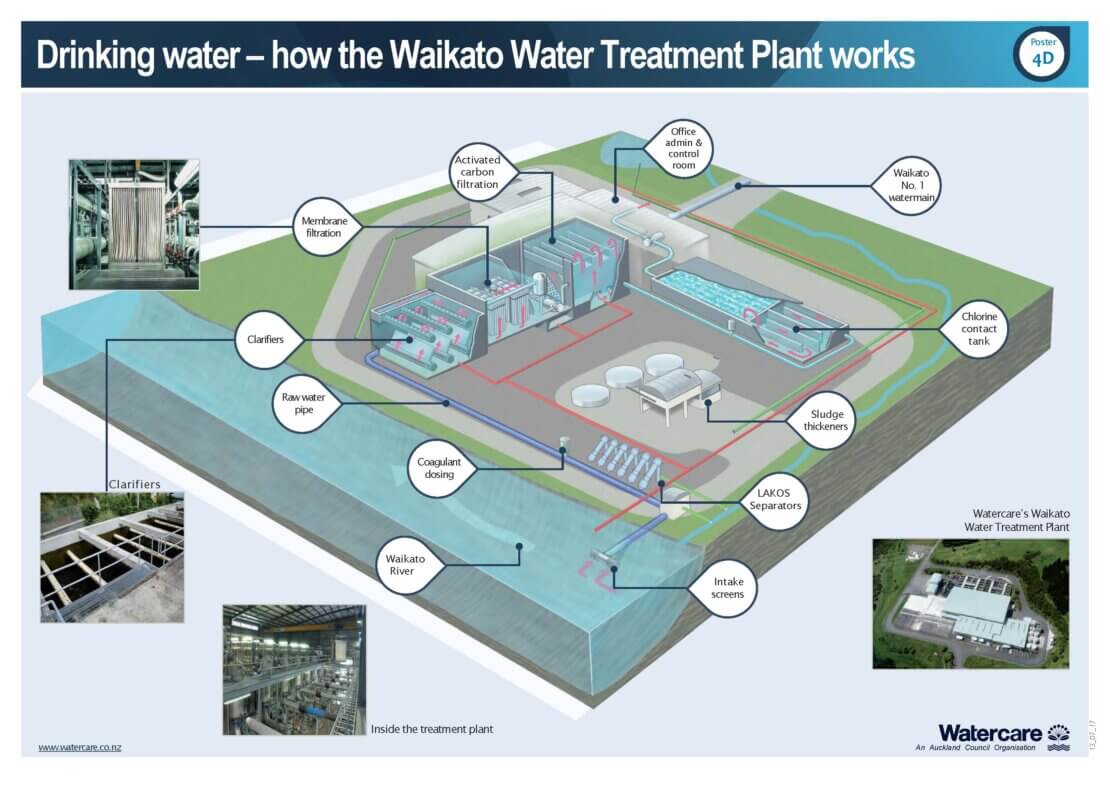

The Waikato Water Treatment plant (WWTP) pulls water from the Waikato River providing drinking water to the city of Auckland, New Zealand’s second largest city.

To meet the demands of forecasted population growth, WWTP was upgraded in 2013-14 to provide a treated water capacity of 150 ML/d (27,000 US GPM). Since then, the WTP has further expanded to now produce 225 ML/d (41,277 US GPM) of treated water.

Problem

When system flows exceeded 75 ML/d (14,000 GPM), excessive sand accumulated in the clarifiers, and created challenges in meeting daily production goals.

To remove excessive sand, the WWTP was forced to manually clean the clarifiers, which was both expensive and time-consuming. As a result, frequent maintenance impacted the plant’s performance and reduced its overall intake capacity and limited the water supplied.

LAKOS collaborated with Watercare (WTP Plant Operator) & Beca Engineering, to identify a solution that would filter the river water continuously and eliminate the need for plant slowdowns and labor-intensive manual cleaning.

Solution

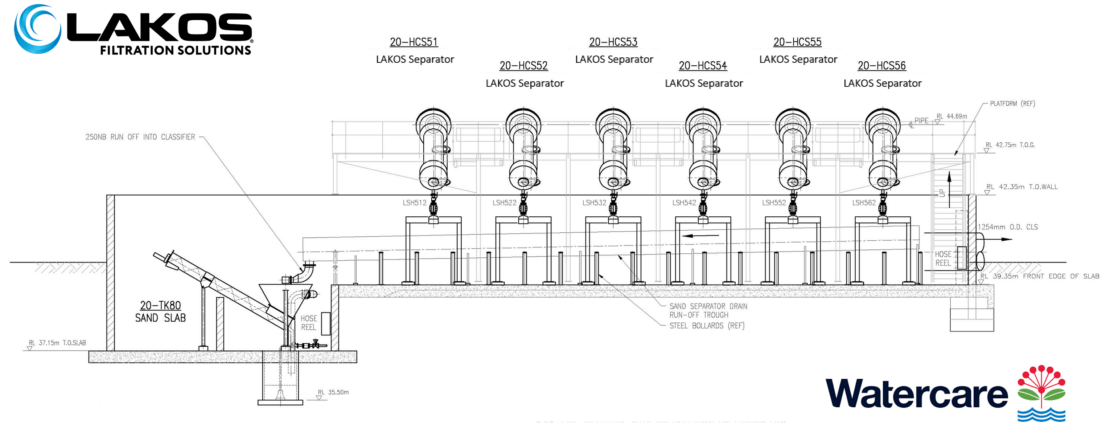

To meet the WWTP’s desired flow rates six PSK-4200 Separators were installed. Each PSK Separator, flowing as high as 42 ML/d (7,800 US GPM) was integrated into a custom solid purging system to collect and remove the high volume of river sand. Also, Separators were coated with 3M Skotchkote 134 material to protect the carbon steel body from brackish water.