Metal Rolling Manufacturer Improves Product Quality, Reduced Labor Costs, & Saves Water

Metal Rolling Manufacturer Improves Product Quality, Reduced Labor Costs, & Saves Water

Application: Tank Cleaning At A Metals Manufacturing Plant

Solids: Metal Scale Liquid: Basin Water

Problem: A large manufacturer of rolled metals in Kentucky produces finished metals for everything from automobiles to military defense projects. With that kind of responsibility on the line, product quality is the number one priority. So when they began to experience labor and product quality issues on their product line, they knew something had to be done.

In the metal coating area, the metal rolls are first sprayed with water to remove any metal scale. The dirty water then falls into a tank, through a heat exchanger, and finally back to the spray nozzles.

Over time, scale began settling in the tanks and re-entering the loop system, clogging up the heat exchangers and spray nozzles. This negatively affected the overall quality of the finished product, and resulted in unnecessary maintenance costs for the company.

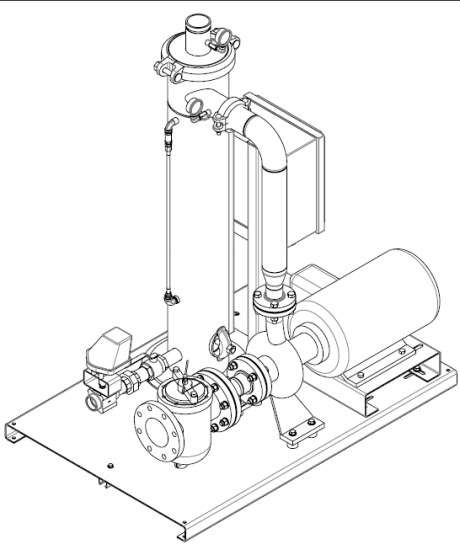

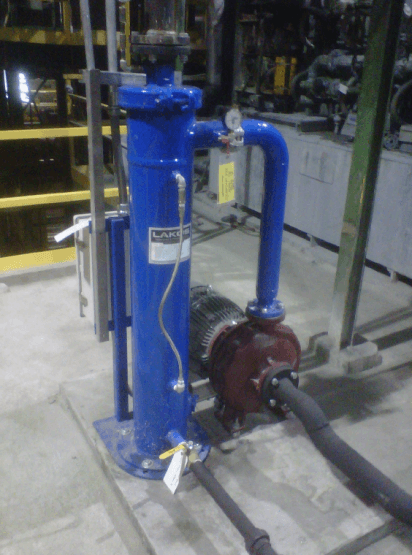

Solution: When a Sunsource representative heard about the problem, he recommended the LAKOS JCX tank cleaning package. The plant engineer was greatly interested and moved forward with the LAKOS Portable Test Rig which proved successful and verified that a LAKOS system would fix the problem. The JCX-0225 system was ordered and installed.

Results: The LAKOS system has been a huge success for the plant. The tank previously needed to be cleaned as many as three times per week, but has only been cleaned twice since the addition of the JCX package six months ago. The plant engineer stated that the labor costs alone were approximately $100.00 per cleaning, with a monthly estimate of $1000-$1500. That works out to $12,000 – $18,000 each year.

With those kinds of numbers, the LAKOS JCX tank cleaning system will be paid for within 8 months from date of installation. That’s not even including the improvements made to product quality, reduced labor costs due to downtime, and water savings.

The plant engineer has deemed the LAKOS installation so successful that he has ordered another JCX-0225 as well as two JCX-0525 systems for similar applications!