Coal Field Processing Plant Reduces Pump Wear

Separator System Used to Reduce Pump Wear in Coal Plant

System Pays for Itself in Four Months

Application: Northern Appalachian Coal Field Processing Plant

System Identification: LAKOS JPX Separator on Plant that Handles 1500 Tons Per Hour

Solids: Coal Slurry

Liquid: Gland Water Used to Seal Slurry Pump Shafts

Problem/Challenge: Piston Pumps Wearing Prematurely Due to Solids in Gland Water

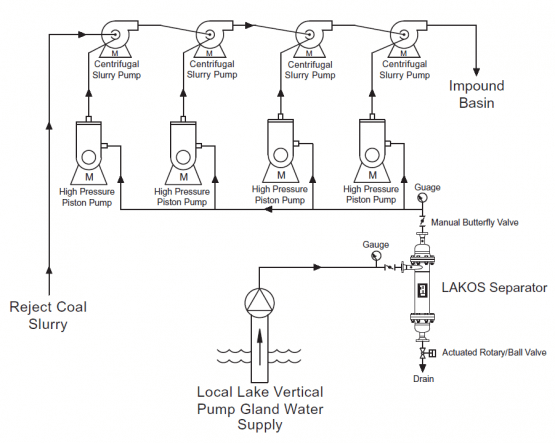

Problem: This plant has four slurry pumps arranged in a series, pumping reject coal slurry to an impoundment located on an adjacent mountain top. These pumps are important to the entire plant because the plant cannot process clean coal without the slurry pump system operating. Clean, high-pressure gland water is critical to the operation of the slurry pumps to ensure optimum performance of the packing seal rings. To accomplish the high-pressure gland water requirement, a piston-type pump was used to inject high-pressure gland water into the slurry pump packing chamber. Previously, a desander was used in an attempt to clean the water before it being introduced into the high-pressure piston pumps. The running clearances of the piston pump are very tight, requiring clean water to maximize piston pump life.

The desander could not adequately clean the water, causing premature piston pump failure. The customer was having the pumps repaired every three months at an average cost of repair of $2,000 per pump. The total average annual cost of repairs of the piston pumps for the system was approximately $32,000.

Solution: A LAKOS Separator system was installed, reducing piston pump repairs from 16 units per year to four units per year. It was further determined that the four units that required repair were due to mechanical problems and not water turbidity problems. The initial cost of the LAKOS system was approximately $4,000. The customer determined the system paid for itself in the first four months of operation.