Auto Assembly Plant Reduces Paint Defects

Paint Defects Reduced in Auto Assembly Plant With LAKOS

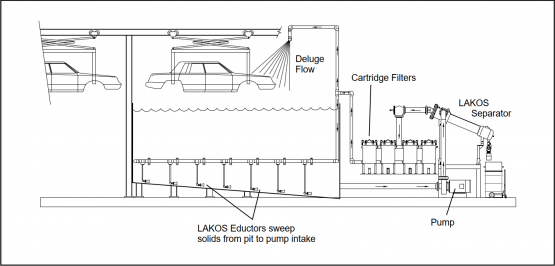

System Identification: Body wash and pre-phosphate wash in an automotive assembly plant.

Solids/Liquids: Weld balls, grinding fines, and slag, atmospheric dirt; water

Problem: A major Detroit auto manufacturer faced unacceptable levels of paint defects and noticeable blemishes on finished cars due to an inadequate and costly performance from existing bag filtration. The assembly of a vehicle body requires several steps, each of which may contribute undesirable solids leading to contamination during the painting process. Welding of the panels and side posts to the frame generates weld splatter, while finish grinding contributes additional grinding fines and slag. Dirt in the atmosphere may also adhere to the panels. This contamination must be removed from the vehicle before initial surface prep, known as the phosphate stage, to provide a smooth surface for the painting process.

In the painting process, multiple coatings are layered to achieve the final appearance. Contamination on the metal surface before the first coat of phosphate can be a noticeable blemish on the finished car once covered with five layers of coatings. While benchmarks have been established to allow for a certain number of blemishes per body panel, numbers beyond acceptable limits require manual inspection and hand refinishing, resulting in higher costs and inefficiencies. While bag filtration was effective for the removal of fiber fines (in the 150-400 micron range), they did little to address the removal of the other major contaminants attributed to blemishes, weld balls, and grinding fines. Using finer-rated filter bags caused maintenance and cost issues, while the larger-rated bags allowed too many potential paint defects. The bag filters were ineffective in eliminating the weld balls and grinding fines which led to costly paint defects.

Solution: Recognizing the need to remove all of the solids problems in their pre-phosphate body wash operation, the auto manufacturer-installed LAKOS Separators on the wash-water recirculating line before the bag filters, efficiently pre-filtering to remove the weld balls, grinding fines and slag. Use of the separators to remove these heavier solids now allows the bag filters to concentrate only on the removal of the fibers and sealant, maximizing filter bag life and increasing the efficiency of the larger micron-rated bags. As a result, paint defects have been reduced by as much as 85% in some plants, further establishing the effectiveness of LAKOS in the auto assembly process. This process has now been adopted worldwide for this auto-maker.