Ice Rinks Problems for Closed-Loop Chilling System

Ice Rink Solves Maintenance Problems for Closed-Loop

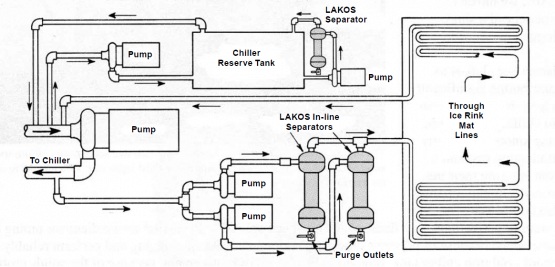

Chilling System With LAKOS Separators

Three Lakos Separators now play a major role in extending the life of an aging ice rink in Pawling, New York. By removing rust and scale created within a closed-loop chilling system, the separators save Trinity-Pawling School over $600 a month in repair and maintenance and help keep the ice rink’s surface solid. “Before installing Lakos Separators, the mat lines under our ice rink clogged at least twice a week,” said Ed Hauser, school plant director. “That caused the ice to melt and forced us into extensive and unscheduled downtime and repairs. In the past two years of using Lakos, we haven’t experienced a single clogged line.” Hauser sees Lakos as contributing significantly to keeping their 30-year old chilling system operating smoothly. Eliminating rust and scale from entering their mat line system, the separators also compensate for other system imperfections. Mat lines, which had been spliced with smaller inside diameter piping (1/16” in some areas) because of previous clogs, are no longer in the risk of clogging and perform reliably. The school’s old iron chiller tank, thought to require replacement because of the problem of the solids, is also no longer a concern, because a Lakos Separator now removes rust and scale which used to pass from the tank into the mat lines.

“We’ve saved considerably by not losing methyl glycol chilling solution which discharged when mat lines burst. It ruined the mat lines and lost 10-15 gallons of the $3/gallon chilling solution each time. It would take a serviceman anywhere from six hours up to a full day to repair one clogged line,” said Hauser.

Trinity-Pawling turned to Lakos in search of a better filtering method after having tried screens and strainers. “Other filters would keep building up pressure as they became full of particles and blew open,” said Roland Lakin, rink mechanic. Lakos Separators, instead, maintain a steady and low-pressure loss and continuously remove solids without screens, cartridges, strainers or filter media to clean or replace. And now, rather than shut down the system to clean filters, a manual valve is simply opened for 10-15 seconds to flush separated solids which have accumulated in the separator’s purge chamber.

Originally removing large amounts of solids and purging every 2-3 hours, they now have cleaned up the system considerably and only purge once every 2-3 days. The school, no longer having to repair clogs in their system, is saving repair costs, man-hours and gallons of a chilling solution … and now have solid ice all year long. Ed Hauser is pleased with the way their Lakos Separators are outperforming all other filters, saying “Lakos Separators did the job that other filters could not.”