Gerawan Foods, Inc. of Sanger, California redesigned their pre-washing system for lima beans in order to implement three LAKOS Separators. The Separators improved water conservation and reduced overall bean damage. Gerawan Foods, Inc. saved over $2,700 annually, completely eliminating silt problems, and dramatically reduced sewage and operating costs. Learn More

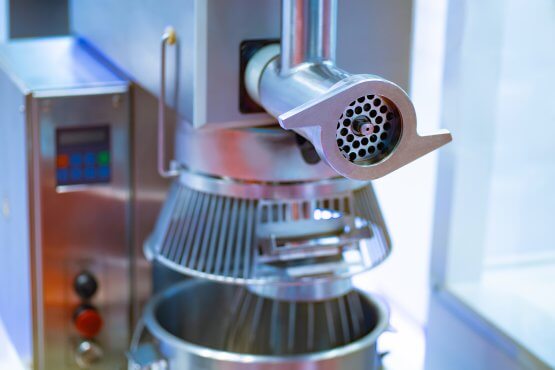

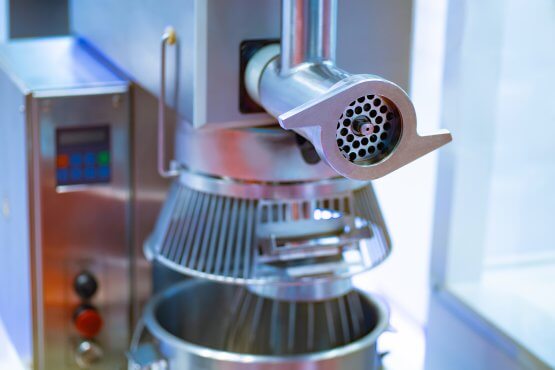

Chuck’s Pump Service of Medford, Oregon chose a LAKOS Separator to clean up the water in their meat processor’s water system due to its many contamination problems. After the installation, the Separator removed sand and grit from the water used to wash the meat. Additionally, the meat processor’s overall network of water piping is benefitting from the installation of the LAKOS Separator. Learn More

A large tomato processing plant in Central California had experienced large amounts of sand in their source water leaving dirt on their tomatoes. The plant looked to LAKOS for a solution and installed six Separators on their main pumps. The Separators removed solids from the water supply reducing wear on the plant’s processing equipment and increased product quality, resulting in labor savings. Learn More

During sugar cane processing, different quantities of dirt, solids, and grit are loaded with the stalks and can be carried into the juice extraction process. In order to remove the bulk of solids, a LAKOS Super Separator was installed and allowed the sugar cane mill to reclaim valuable sugar cane juice while limiting juice loss. Learn More

The Pujiltic Sugar Mill in Chiapas, Mexico worked with LAKOS to develop a complete solids handling system to reclaim additional sugar juice from discarded fibers. After working with LAKOS, the sugar mill limited the loss down to 0.08% and is able to remove up to 35 tons of sand and dirt from the 7,000 tons of raw sugar processed daily. Learn More