When frying potatoes in oil, carbon residue quickly builds up in circulators, heat exchangers, and in fryers, which reduces efficiency and causes damage to machinery. To solve this issue, six Western states food processing plants installed 11 LAKOS AXL Series Separators allowing little to no carbon residue buildup, maintenance, cost savings, and improved FFA readings. Learn More

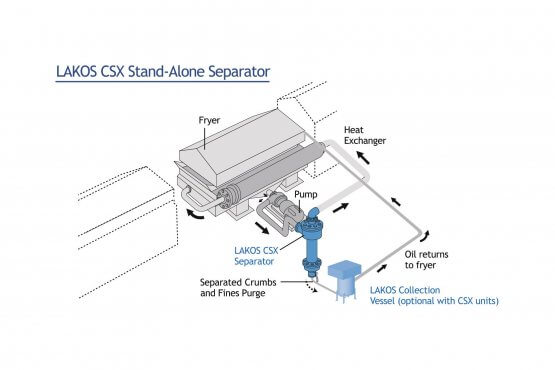

A yucca chip processor in Ecuador was looking for a way to extend the life of there cooking oil before replacement. However, due to the accumulation of burnt yucca crumbs and fines in the oil, they noticed a drop in chip flavor and appearance and required the oil to be replaced frequently. The plant hastily installed a LAKOS CSX Separator with a crumb box to allow for continuous filtering, increasing oil life by 50%. Learn More

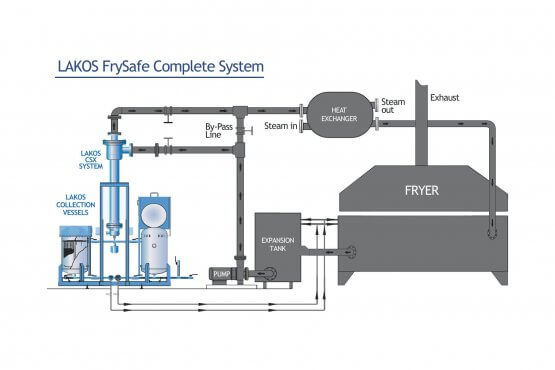

The build up of solids in a heat exchangers tubes at Backer’s Chips in Fulton, Missouri caused significant clogging problems. The clogging stopped the flow of oil in the tubes and would eventually melt the tubes. Backer’s Chips quickly installed a stainless steel LAKOS FrySafe System in order to remove crumbs and chip pieces before they reached the heat exchanger to prevent the tubes from clogging. Learn More

Snack food companies want their food to be fresh, crisp, and full of flavor while using as little oil as possible. This proved to be quite a challenge for one of the largest snack food manufacturers on the East Coast of the U.S. due to the many problems cooking oils encounter during the frying process. Eight LAKOS CSX Separators were purchased and installed and has extended the life of the cooking oil, producing a better tasting and better looking product. Learn More